Despite the roof type, other factors impact the selection of roof coating, as roof coating offers tremendous strength and additional protection and enhances the longevity of the roof surface.

The choice gets complicated when users come across multiple brands and versatile products, and that’s when users cannot get what they desire.

It’s of prime importance to know the available roof coating types and their nature, along with flat roof coating properties.

For that, we are here to help you get the most relevant and knowledgeable info to help you get the roof coat per roof material.

Always remember that a slight mistake in selection adds additional wasted cost to the user’s budget, and that’s why a handy guide informs about the relevant factors to remember before going for the best flat roof coatings.

| Best Flat Roof Coatings | |

|---|---|

|

APOC 585 Armor Flex Liquid Silicone Check Price |

|

Henry TropiCool 5GAL Silicone Roof Coat Check Price |

| Countryman Coatings Silicone Check Price | |

|

Henry HE587372 Elastomeric Roof Coating Check Price |

|

Jetcoat Cool King Reflective Acrylic Roof Coating Check Price |

|

AMES RESEARCH LABORATORIES Stretch Roof Coating Check Price |

Type of Roof Coating

Most commonly, users need roof coating based on their roof type.

For a flat roof, the best layer among elastomeric ones includes the silicone coating that lowers the cost of replacement and maintenance and not only reduces the roof leakage while enhancing longevity, low energy intake, and provides reactivity and safety from UV.

So that’s how a flat roof gets protected. Still, in case users in demand of acrylic ones should only consider them to avoid tearing or installation issues, low purchasing cost, and high suitability. Let’s discuss in detail insight for each type.

Main Types

- Acrylic coatings

- Asphalt coatings

- Polyurethane coatings

- Silicone coatings

- Single ply-membranes

Other Types

- Butyl resins coating

- Fluoropolymer coating

- PMMA coating

- Polyester coating

- Silyl terminated polyether coating (STPE)

- Polyuria coating

- PUMA coating

- SEBS coating

- Styrene-acrylics coating

So, we make the details about each main roof coating type that help you understand what they are.

How are they helpful for you, and where can you use them?

Acrylic Coatings

The acrylic coating seems to be one of the most common coats for surfaces and substrates, including modified bitumen, metal, built-up, single-ply, and spray polyurethane foam.

The acrylic coats require the substrate to offer mechanical firmness to keep the coating intact.

The acrylic coating seems best if your rooftop owns any of the above substrates. Avoid using acrylic for board sheathing, groove decking, tongue, shingled roof surfaces, and plastics.

Asphalt Coatings

In the US, most homeowners opt for asphalt shingles as a roofing material.

Still, they also seem prone to wear out over time, so asphalt coatings get on the market to protect those surfaces and enhance longevity.

Shingles self-offer high-quality roofing with an architectural and aesthetic look, but with a coat, users get additional years of safety and protection, reducing the additional maintenance cost.

Single-Ply Membranes

Single-ply membrane favors roofs with low low-sloped nature.

Having one such roof would make you invest in single-ply membranes because that adequality gets compatible with such roof surfaces and gets intact in the form of a membranous layer to add additional safety.

Polyurethane Coatings

Polyurethane coatings suit roofing substrates like EPDM, BUR, single-ply, concrete roof deck, and modified bitumen.

However, 02-variants, including aliphatic polyurethane and aromatic polyurethane, are designed to coat these substrates with a versatile coating.

Silicone Coatings

A flat roof surface enhances reflectivity and effectiveness, considering a silicone coating lies best in the list of roof coatings.

Areas with high rain or water ponding issues must consider silicone roof coating rather than acrylic because they won’t get washed off with rain.

Instead, protect the surface. 02 silicone variants are less costly, with metal protection capabilities, including acetoxy-cure and oxime-cure silicone roof coatings.

What to Consider When Choosing the Best Flat Roof Coating?

Considering roof coating would make you go through versatile products available in the market, each ensuring better protection, safety, integrity, strength, and low tearing off.

But which one would be best for your roof type, and how to select the best flat roof coating to eliminate those harsh factors while keeping an evil eye on the rooftop?

To select the best roof coating for the roof surface, consider these factors: roof type, installation ease, environmental variation, longevity, and resistance.

In resistance, check the coating resistance for water, weather, solar reflectivity, and cracking or peeling off.

What other factors would help select the coating type? No idea? Well, a handy guide will help you learn about roof coatings and the best available in the market.

Ease of Application

Going for a roof replacement creates too much disruption and high cost, which needs to be solved by selecting the best roof coating.

But before choosing the roof coating, users must consider the ease of application factor because the more manageable the layer, to less you get tired of or the lower the labor cost.

Despite the ease of use of an acrylic coating, the coat isn’t suitable for flat roofs prone to rain or water ponding issues because the water-soluble acrylic coating gets dissolved within a few rain showers and washed off.

So, areas with frequent rain and flat roofing should have a silicone roof coating.

Applying the roof coating would be much easier upon a maintained, cleaned surface than a poorly cleaned roof, so before using it to coat, ensure you get a cleared top free from dust, grime, mold, or other interfering particulates.

The silicon coating is a bit hassle because removing the wrong part requires time and cost, requiring professional experts to complete the task.

Silicone coating requires mania and spray guns to apply even coats, making the coasting hassle if not well trained.

Drying time also plays a role in selecting the roof coating.

If the roof is suitable for acrylic and silicone, then consider ease of application and drying time because the more straightforward application with quick drying time, the less hassle the work.

The acrylic coating gets applied in dual layers, one after each upon frying. The standard drying time depends upon the thickness and nature of the coating.

The acrylic coat dries out in 20 minutes or may take up to 02 hours, while the silicone coating takes an initial 02-04 hours to dry and may take a day to cure.

So, consider the roof coat providing easy support; do not get in your comfort zone while compromising on the coating type because ease isn’t of any use without compatibility.

Longevity

Here comes the crucial factor in choosing the best coating for a flat roof: each coat’s longevity feature.

Longevity is when a roof coat stays long-lasting and offers a protective and resistive function.

The longevity can vary based on durability, quality, brand, and roof coat nature, but coatings generally provide 10+ years of protection.

If the flat roof has water ponding issues, silicon roof coating seems the best, offering almost ten years of protection.

Still, compared to acrylic coating, the average life span of the layer gets more than 18 years if maintained.

If roof coating gets warranted for ten years after reapplication or recoating, the longevity gets enhanced and restarts with a new warranty of 10 years.

Roof coating longevity directly causes the roof material to stay longer and often avoids replacement.

The higher the longevity, the more it extends the protection and reflectivity to prevent additional roof maintenance costs.

Now that you know the longevity of 02 popular coatings for flat roofs, consider recoating with a gap of 05 years and not more.

That is because the environmental conditions, factors, and other cases might lower the longevity, and timely recoating can prevent late shortcomings from the roof.

So, it’s advisable to recoat your flat roof every 05 years despite the longevity to keep the protection on top priority.

So, once you apply a silicon or acrylic flat roof coating, go for the subsequent layer after 05 years in case of any damage due to harsh conditions.

Otherwise, they live more than that, so there are no worries till any physical damage gets seen over time.

For more precise knowledge, consider user reviews for the specific product to understand better the actual worth of the product you opt for, the flat roof.

Indicators Of the Environment

Environment plays a crucial role because the roof always seems prone to all environmental changes in the form of weather changes and other factors like pollution, dust, etc.

Environmental indicators provide information about the current surroundings by measuring the parameters and informing the users.

Among the environmental indicators that cause an effect on the roof surface include climatic changes, changes in pressure, greenhouse gases, global mean temperature, emergency intensity, and many more.

Among them, the most common factor is the climatic and weather changes. Geographical location also plays a more significant role because each kind of rooftop and coat varies from a geographical point of view.

Keeping in mind that the flat roof remains under environmental change effect, causing it to wear out over time, matte roof coating breaks the direct contact and pushes insulation over the rooftop to ensure its protection, safety, and longevity.

The coating color also imparts its effect alongside the environmental change for white roof coats; not only is reflectivity reduced by thermal conduction also seems less compared to darker roof coatings that absorb thermal energy.

For hot or rainy areas with flat roofs, white silicon roof coating seems a better choice than a darker shade for layers.

Resistance

Resistance means opposing force, and coating resistance plays a significant role for the roof because there seem to be many factors that the coat needs to abide by, offering variable resistance.

A good flat roof coat must be water- and weather-resistant if a flat roof has water ponding issues or more frequent rain.

For a flat roof, consider the coating with high reflectivity to cause resistance against UV, while resistance to cracking should be another factor the coat needs to provide.

The roof coating can vary and offer variable resistance based on the flat roof material and type.

A. Water Resistance

Flat rooftops and surfaces need complete protection from moisture and water; for that, they acquire water-free or lipophilic roof coating; the most common include silicon roof coating. For water, resistivity considers the perm factor.

Perm indicates the terms related to moisture transfer. The lower the perm value, the better moisture resistivity by the roof coating.

The characteristics seem high, 50 perms for acrylic coating, while the silicon offers just 05 perms.

Despite these, membrane coatings also provide good water tightness, enhancing water resistivity and preventing moisture or water from directly absorbing. Choose the flat roof coating with the most negligible perm factor.

B. Weather Protection

One of the environmental indicators seems to be the climate and weather change that, over time, directly affects the roof surface, making it prone to breaks, cracks, water ponding, and many other issues.

A flat roof coating would be an excellent choice to protect the roof surface from harsh weather.

For less rainy areas, acrylic ones suit you best. Windy areas and hot areas would prefer the ones with high reflectivity.

For rainy conditions flat roof isn’t a good choice, and coating with silicon can protect up to a limit. Snowy regions own slopped roofs, especially metal, that may require another type of coating.

C. Solar Reflectivity

Solar reflectivity is the ability to withstand harmful UV rays that cause the roof surface to wear out over time.

The better the resistivity values offered by a roof coating, the more compatible the layer gets for flat roofs. The best roof coat offers more than 90% UV resistivity.

To ensure the coating product has the highest resistivity percentage. Henry, a top brand for roof coating, provides all types of roof coating, and among them, the silicon ones offer much more UV protection with high reflectivity than the acrylic ones.

The difference seems less but impacts the roof. EPDM best suits offer higher resistivity if the flat roof owns a rubber substrate.

D. Cracking

The flat roof coating must be crack-free, so elongation factors need to be considered for roof coating.

Elongation seems to be the movement of the coat with the roof surface and its ability to lower the chances of cracks.

The higher the extension, the less chance of cracking. For acrylic roof coating, elongation is reduced more than silicon roof coating (silicone offers better elongation properties).

A 100% acrylic coating offers 100% elongation, while a silicon roof coating offers 174%, as rated by experts and users.

These percentages apply to newly applied roof surfaces, but both still offer their best when the coat ages. Overall, the elongation of silicon coating seems much higher than the acrylic ones.

Our Top Silicone and elastomeric Flat Roof Coating

Now that you know how to select the best silicon flat roof coating, it’s time to get introduced to a few top products users love to opt for their flat roofs.

Products satisfy all the guide factors and ensure you make your surface now more than before with long-term protection from all the harsh conditions.

So, in search of flat roof coatings, try these silicone roof coatings to make the surface barrier much more effective and more robust.

Elastomeric roof coatings are liquid adhesive coatings applied on versatile root surfaces, preventing cracks and crevices and maintaining a clear and protective covering.

The elastomeric name came from elastomer, a combination of polymers that opted for different roof types based on the conditions, roof type, environmental stress factors, and many other issues for the roof and surface.

The additional elastomeric coating seems available to protect the top from moisture or UV rays, so ensure the correct type for the suitable surface with the proper method.

1. APOC 585 Armor Flex Liquid Silicone

| Material | Carbon compatible material |

| Technology | Pond-proof technology |

| Use | Designed for professional experts |

Features

The white Armor Flex Silicone Roof Coating provides high protective and tensile functionality with 05 gallons per container for your roof to avoid water ponding issues and heat gain.

The white reflective coat helps to provide better reflectivity with no heat gain and offers a fantastic living site inside the house.

The fabulous coat also reduces the energy cost uptake to cool the room in the summer because, at that time, standard non-coating flat roofs may absorb high heat, causing enhanced inner temperature.

But with Armor Cool coat sheet, your rooftop is the best flexible material to provide extended coverage and protection over many years.

The best part about the APOC armor flex is that the product allows solvent-free application with green-engineered products using only traditional solvents that protect the surface and prevent the environment from getting polluted with harmful solvents that evaporate over time.

No matter how bad the weather, the coat remains intact and flexible over long durations, protecting the roof from rain, UV, and heavy storms.

Get rid of ponding issues all because of the Pond-free Technology of the lipophilic nature coating.

Always ensure low foot traffic because silicone is more prone to damage than heavy foot traffic.

- Formidable and intact barrier

- Solvent free material

- Low carbon emissions

- Heavy foot traffic might cause damage

2. Henry TropiCool 5GAL Silicone Roof Coat

| Made | 100% silicone-made roof coat |

| Resistant | UV and water-resistant |

| Bucket | 05-gallon bucket |

Features

You might know the name of Henry that provides the best silicone roof coatings for all roof types, so to get one for your flat roof, go for Henry HE887HS073 Tropicool prevents moisture from getting inside your roof coating.

The matte roof coat also protects it from the harsh UV rays that usually deteriorate and wear out flat roofs.

With reducing energy bills and providing the best protection, Henry is always the favorite brand of many users.

The product comes in a 5-gallon bucket offering a white coat that does not need the addition of any solvent; instead, directly applied using any suitable ¾ inch roller, spray, or any device as per your convenience.

You get a superior, highly durable coat with water resistance and high reflectivity features.

Users living in extreme climatic conditions for the tropical environment are supposed to use the Henry low silicone roof coating for their roof types to protect them from multiple extreme conditions.

The coat keeps rain away from getting pounded on the roof surface.

Always remember that silicone roof coatings are non-washable with water like the acrylic ones so far that you need a special solvent in case you want to peel off the coat in case of any wrong application.

Henry has won many hearts by providing the best coating with a few gallons.

- Durable coat

- Weather resistant

- White reflective coat

- Compatible with few roof surfaces

3. Countryman Coatings Silicone

| Reflectivity | 90% UV reflectivity |

| Use | 01 gallon for 55 square feet |

| Resistant | Water-resistant |

Features

Don’t waste high costs for replacing the rooftop where you can spend less and get a new one like before, but how’s that possible?

Opt for the 100% silicone top coat that comes in a versatile quantity ranging from one gallon to a quart.

The silicone roof coating suits gravel surfaces, single-ply concrete, EPDM, etc.

Those users complaining about worn-out rooftops because of Harsh environmental conditions and rain creating water ponding issues can use the 100% silicone roof coating to avoid UV rays with 90% reflectivity and better eliminate water ponding issues.

With protection, the coat also lowers energy utilization by up to 20% and offers an excellent top coat; before purchasing, measure your surface area and opt for the required gallon.

For 55 square feet, you would require one gallon of the silicon topcoat. You can coat your RV with silicone coating and prevent it from drying out for many years.

The best thing about the coat is that it’s available in multiple colors, but opt for the white paint to achieve more excellent reflectivity.

Besides that, you get grey and black based on location and environmental conditions.

For a professional look, you can opt for a roller, spreader, or spray to coat the silicone coating over your flat roof.

- Weather resistant

- Durable

- Reduce energy bills by up to 20%

- Not prone to high foot traffic

4. Henry HE587372 Elastomeric Roof Coating

| Reflectance | Initial reflectance up to 70% |

| Resistant | Water-resistant |

| Bucket | 05-gallon product |

Features

A metal, buildup, or rolled roof system requires a good covering, usually elastomeric, then consider the Henry HE587372 elastomeric roof coating.

The product provides a long-lasting ten-year warranty and retains initial reflectance of up to 70%, while lowering the surface temperature provides a more relaxed inner site.

With Henry, no water ponding issues exist with resistance to molds and other particulates that affect the roof.

The product comes in a 5-gallon bucket approximately suitable for 100 square feet, so a total of 18 ml would be easily applied to a 100 square feet area and prevent an intact white elastomer coating to the surface from deteriorating from any of the factors or other environmental indicators.

Henry products Always seem to be the favorite of many professionals and are considered the number one choice for all efforts for their roof coating.

The product contains resins, Titanium dioxide pigments, and fillers that enhance the coating strength and prevent cracking with better solar reflectivity.

Some roofs require a primer before going for coating, but in the case of Henry, you don’t need to opt for a primer directly applied using desired tools to get an even coat.

- Ten years warranty

- God coverage up to 100 square feet per gallon

- No need for primer

- Slippery coat

5. Jetcoat Cool King Reflective Acrylic Roof Coating

| Drying time | Drying time 02-03 hours |

| Resistant | UV resistant |

| Warranty | 05-year warranty |

Features

To adequately coat your EDPM rubber roof, modified bitumen, polyurethane, wood, concrete, asphalt, mobile home, or RV roof surfaces, all you need is to opt for the jet-cool acrylic white reflective roof coating.

The coat provides a seamless array of roof coats that prevent UV damage and keep the roof safe for longer.

Instead of replacing rooftops with desired elastomeric coating helps the users get ultimate protection on a low budget compared to a new rooftop.

For professionals, the jet coat seems easy; using a roller or spray, the roof coat gets evenly spread around on a good sunny day with approximately a roof coverage of about 50-70 sq feet.

On general notice, the coating gets dried within 02 or 03 hours, but waiting up to 8 hours may seem a good option. Let the coat completely dry out. Each coat would utilize the time to dry out, so ensure the second coat gets applied properly.

The product contains polyurethane that acts as a rubber roof coating and would help the surfaces look friendly, protective, and better.

The jet coat offers a 05 years warranty that gets renewed upon a new layer. So let the surface get cool and shiny with reflectivity better than standard roof by use of jet coat acrylic roof coating.

- Affordable

- Reflective coating

- Best for RV roofs

- Low coverage than other products

6. AMES RESEARCH LABORATORIES Stretch Roof Coating

| Bucket | 1 Gallon covers 100 sq./ft for a single coat |

| Reflectivity | 88% Reflectivity |

| Resistant | Weather resistant |

Features

Get up to 650% of elastic adhering properties to your roof surface, including metal, roll, and many other roofs.

All you need is a maximum-strength elastomeric roof coating that provides the best rubber coating for up to 12 years with no peeling issues.

The layer comes in a gallon containing 3.785 liters, delivering 88% reflectivity, ensuring transparent, more excellent surfaces.

Apply the coating to the roof where you need rubber roofing, creating a white covering that provides intensive protection to the rooftop, saving it from deterioration in harsh environmental conditions.

The product seems waterproof and usually suits RVs and other metal surfaces with no toxic and eco-friendly nature.

USA-made roof coating includes the MSS1 containing low VOC and can better help you eliminate multiple roof problems with dual coat application.

So, grab a brush and roller and start coating the roof using an AMES MSS1 roof coat to initiate ultimate strength and support to your roof surfaces.

Remember to opt for a roof with a low slope to make the coat come out much more effective and protective.

The white elastomer’s cost adheres well and seems easier to use, but hassle to apply adequately by newbies.

Get a chip and flake-free roofing with the best elastomeric coating, the AMES MSS1 roof coat, and a rubberized roof coating with enhanced versatility.

- 12 years warranty

- No Chip and Flake

- Eco-friendly product

- Hassle while installing

When to go with Silicone Roof Coating

Silicone roof coating favors flat roofs when desired to prevent the issue of water ponding or leakage.

Despite the drainage system, the water gets stagnant, creating puddles that affect the top by interfering with inner buildup. Low-sloped roofs also consider a silicone roof coating.

To get high reflectivity, go with a silicone roof coating. Considering silicone coating won’t be a wrong choice if you want at least 10, 15, or 20 years of protection.

Last but not least, users desiring to get an excellent flat roof, then considering silicon coating would help them achieve the desired energy efficiency factor by reducing the cost by up to 35% and keeping the site heat-free.

No thermal heat gets absorbed under a silicon roof coating. Silicone roof coating also has some problems. You can also know about them.

When to go with Acrylic Roof Coating

Sloped metal roofing or flat roof with a proper drainage system allows users to coat the roof surface using the acrylic roof coating that provides excellent tensile strength and up to specific limit water resistant properties.

The acrylic coating gets worn out even for flat roofs with no drainage, causing water ponding issues.

If the roof type suits the acrylic ones, consider environmental factors. Areas with low rain can opt for an acrylic coat as they seem less expensive than other coatings.

Using acrylic ones seems a better option for low energy bills and excellent inner sites.

For UV reflectance, the acrylic coat also offers good reflectivity %age, so ensure the suitable surface, roof, and surrounding conditions to choosing the acrylic coating.

Acrylic roof coating also has some problems. You can also know about them.

Common Problems Affecting Flat Roofs

The flat roof seems much easier and more cost-effective to build and lasts longer, but no matter how durable the flat roof seems over time, the damage is ordinary in all cases, and why is that so? It’s because of the flowing factors;

- Overexposure: Compared to sloped ones or other roof types, flat roofs are more open to exposure and may be affected by direct environmental and climatic change in the form of high UV exposure, hail, winds, rain, etc.

- Leakage issues: With no proper coating maintenance, the roof material might lose the water integrity and use water to leak down, causing multiple issues. Moisture gets captured and causes future roof issues or affects the roof material badly.

- Water ponding problem: Due to no slope, the water gathers and causes water ponding that affects the fat roofs. So flat roof is more prone to water ponding somewhat sloped.

- Mold growth: When high moisture remains on the flat roof, chances are the growth of fungi and molds that cause damage to the top.

- Prone to high particulates: A sloped roof allows low debris to accumulate, while a single storm can make the flat roof full of additional trash, dust, dirt, leaves, and nearby tree branches. And rain makes the top messy.

Other problems include;

- Tearing

- Shrinkage

- Blistering or Alligatoring

- Prone to thermal movement

How You Can Protecting Your Investment

People spend their best income on worthy properties and own beautiful homes with the best rooftops.

However, investing in a property requires keeping it maintained over time. Here come the problems that seem more specifically related to the root cause.

Roofs seem more prone to extreme environmental conditions and indications.

Hence, spending on affordable or budget-friendly products enhances longevity, productivity, efficiency, and protecting the rooftop to protect your investment.

Opting for a coat is more significant than considering changing the whole rooftop, which costs more than coating. No matter how durable your rooftop seems, it is damaged by weather conditions, climatic changes, and the negative factors that impact the roof.

So, to prevent your 1000 dollars’ worth of investment from going in vain within a few years, you need to settle for the best available coating to ensure the longevity and safety of the desired property.

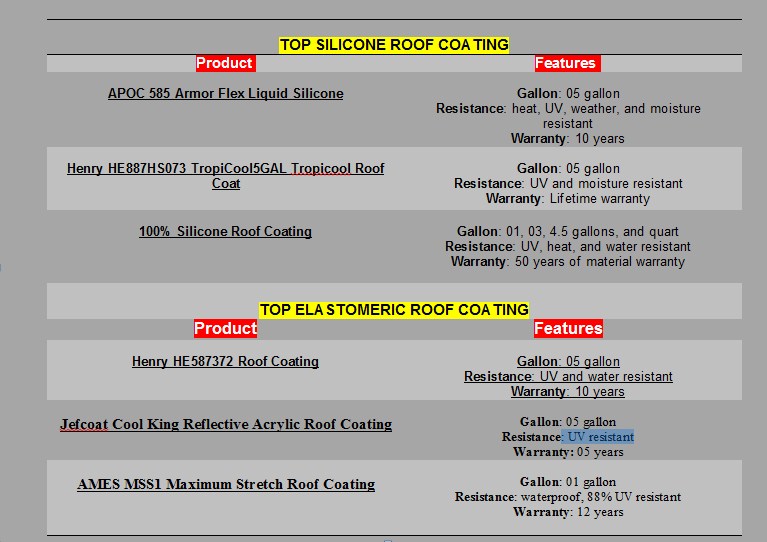

Roof Coating Comparison Chart

Conclusion

Now that you are well-known for the best flat roof coatings available, that seems much easier for you to select the top three from both silicone and elastomeric roof coatings.

Consider your roof surface type and many other factors, making it easy for users to get what they desire without wasting money, time, and energy.

Search for products that suit desired surfaces, accounting for the best applicable products to a worn-out surface.

To avoid making mistakes during selection, consider this handy guide and select your top choices to get the product at the best-desired rate.

We hope you have taken it as a way of getting informed with ease to choose the coat opting for the upcoming coating session.

Frequently Asked Questions

How Much Does Silicone Roof Coating Cost?

Compared to elastomeric roof coatings, silicone roof coating costs more because of its beneficial aspects, heavy machinery and spray use, and compatibility with flat roofs.

Silicone roof coating costs about 02 – 3.5 Dollars per square foot, while acrylic is even less than half of their price, concluding ½$ for $1 per square foot. Ensure your rooftop compatibility with the coating you opted for.

How To Prepare a Flat Roof for Coating?

To prepare your flat roof for elastomeric roof coating, especially in the case of silicone roof coating, the first thing you need to consider is cleaning the roof surface.

Because, over time, the accumulation of dust, dirt, particulates, or grime residing on the flat roof can cause hindrance during coating.

You would require a pressure washer or water hose to effectively clean and use a bristle brush to scratch off mold growth or grime to clean the surface because covering the surface requires a clean surface.

What if the stubborn stains get hard to remove with a water hose or bristle brush? For that, use TSP trisodium phosphate cleaner to remove dirt, preparing the surface for coating.

How Often Should a Flat Roof Be Coated?

Generally speaking, roof coating lasts about 10 to 20 years from the date of its installation till the warranty, but flat roof systems usually last for 10 years.

To increase the roof integrity, strength, and performance, cover the flat roof with silicone coating every five years to add sufficient strength and protective features to stay intact without causing damage to the rooftop.

Arthur is a skilled roof worker with over 10 years of experience in the industry. He started his career as an apprentice and worked his way up to become a foreman.

When he’s not working on roofs, John enjoys with his family or writing posts. He is also a passionate cyclist.